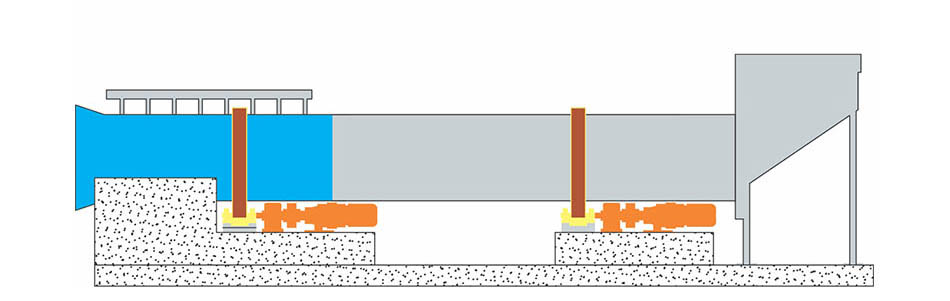

Drum Pulper

| Capacity & Sizes : | ||||||

|---|---|---|---|---|---|---|

| Capacity | 12 M3 | 16 M3 | 20 M3 | 25 M3 | 30 M3 | 40 M3 |

| TPD | 60-75 | 80-110 | 110-160 | 160-250 | 250-300 | 350-450 |

| Consistency % | 4-6% | |||||

| Power (Kw) | 120 | 160 | 185 | 220 | 280 | 315 |

© copyright 2019 Su-tantra Equipements Pvt. Ltd.

Design: Integrate Advertising