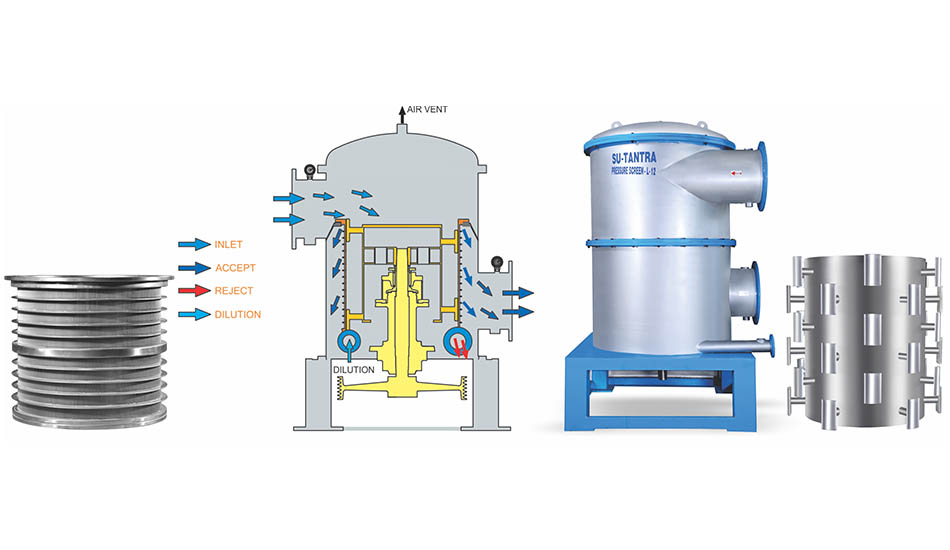

Pressure screen manufacturer

Low consistency pressure screen

Pressure Screen For pulp & paper mill

| Sr. No. | 1. | 2. | 3. | 4 | 5 | 6 | 7 | 8 |

| Model | SVPM-400 | SVPM-500 | SVPM-600 | SVPM-660 | SVPM-800 | SVPM-1000 | SVPM-1200 | SVPM-1500 |

|---|---|---|---|---|---|---|---|---|

| Capacity (T/Day) | 15-40 | 30-60 | 40-80 | 50-100 | 60-120 | 100-250 | 160-300 | 200-350 |

| Power (KW/1440 RPM) | 18-20 | 22-37 | 25-45 | 37-50 | 45-75 | 75-125 | 110-200 | 150-225 |

© copyright 2019 Su-tantra Equipements Pvt. Ltd.

Design: Integrate Advertising