Pressure screen manufacturer

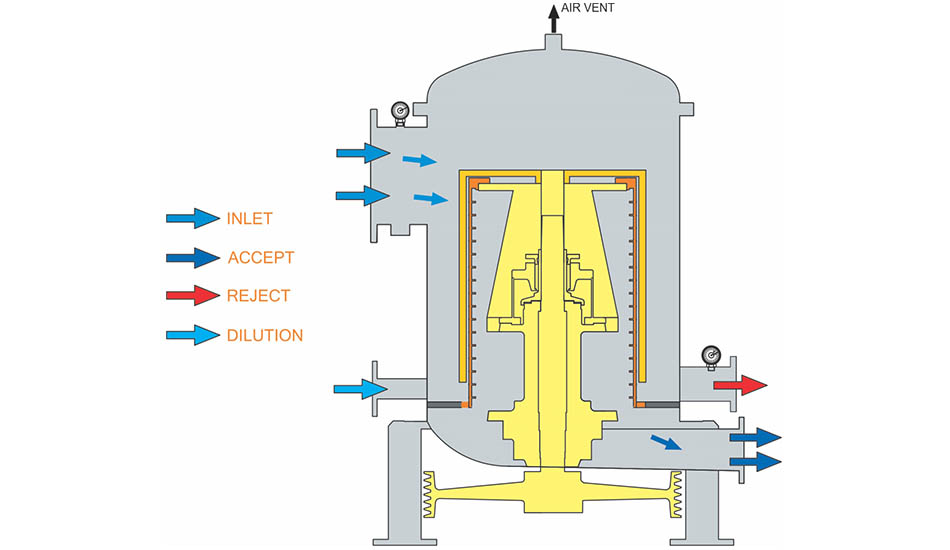

Inflow Pressure Screen

Pressure Screen For pulp & paper mill

| Sr. No.; | 1. | 2. | 3. | 4. | 5. |

| Model | SIFP-500 | SIFP-600 | SIFP-800 | SIFP-1000 | SIFP-1200 |

|---|---|---|---|---|---|

| Capacity (T/Day) | 25-50 | 75-100 | 120-170 | 180-235 | 200-270 |

| Power (KW/1440 RPM) | 15-22 | 30-37 | 45-50 | 55-75 | 75-80 |

© copyright 2019 Su-tantra Equipements Pvt. Ltd.

Design: Integrate Advertising